Natural stone is a material that requires specific quality control measures to ensure the best quality. There are many small details to consider when selecting and installing natural stone, which can be challenging to determine from a distance or without expert guidance. Over the years, we have gained extensive experience working with various properties, establishing ourselves as the ultimate destination for top-notch natural stone solutions. Our experienced and well-trained team offers guidance to clients in all aspects of selection, installation, and care.

What Indicates Good Quality Stone?

Identifying good quality stones is crucial, as it determines natural stones’ durability, longevity, and aesthetic appeal. To identify good quality stones, you must consider several factors, such as the type of stone, colour and texture, surface finish, and resistance to wear, staining, and other forms of damage. By understanding these indicators and selecting stones that meet your specific needs and preferences, you can ensure that you are investing in high-quality, long-lasting, and visually appealing stone products for your home or business.

Considerations of Various Matters

1. What to Look for When Choosing Quality Stone for Countertops

2. The Science Behind the Durability and Longevity of High-Quality Stone

3. How the Colour and Texture of Natural Stone Can Add Value to a Place

4. The Surprising Benefits of Investing in Quality Stone for Landscaping

5. The Environmental Impact of Choosing High-Quality, Sustainable Stone

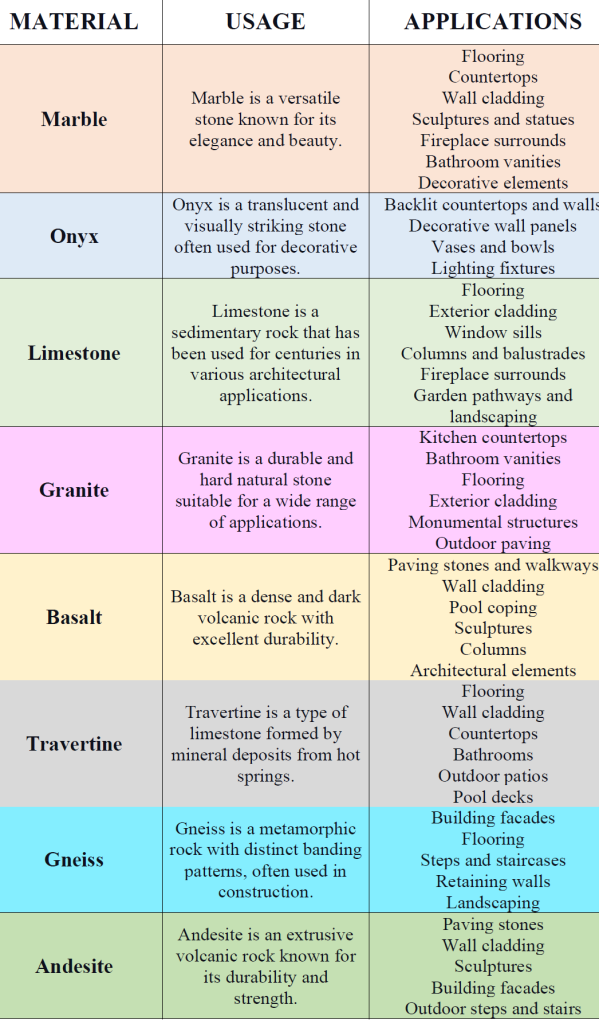

Key Factors to Consider and Specifying the Usage

Throughout history, natural stones such as marble, onyx, limestone, granite, basalt, travertine, gneiss, and andesite have been used for various purposes due to their unique characteristics. However, it’s essential for end-users to identify the most appropriate material for their specific usage.

Important Elements for Determining the Quality

1. COLOUR MATCHING: Selecting natural stone materials involves considering colour matching as a crucial aspect. Different stones, like marble, with a spectrum from pure white to nearly black, often have softer tones. Limestone’s colour varies based on mineral composition, while materials like granite and onyx provide diverse, even unconventional, colours. Achieving the desired aesthetic requires careful consideration of colour, making it an essential factor in choosing stone materials.

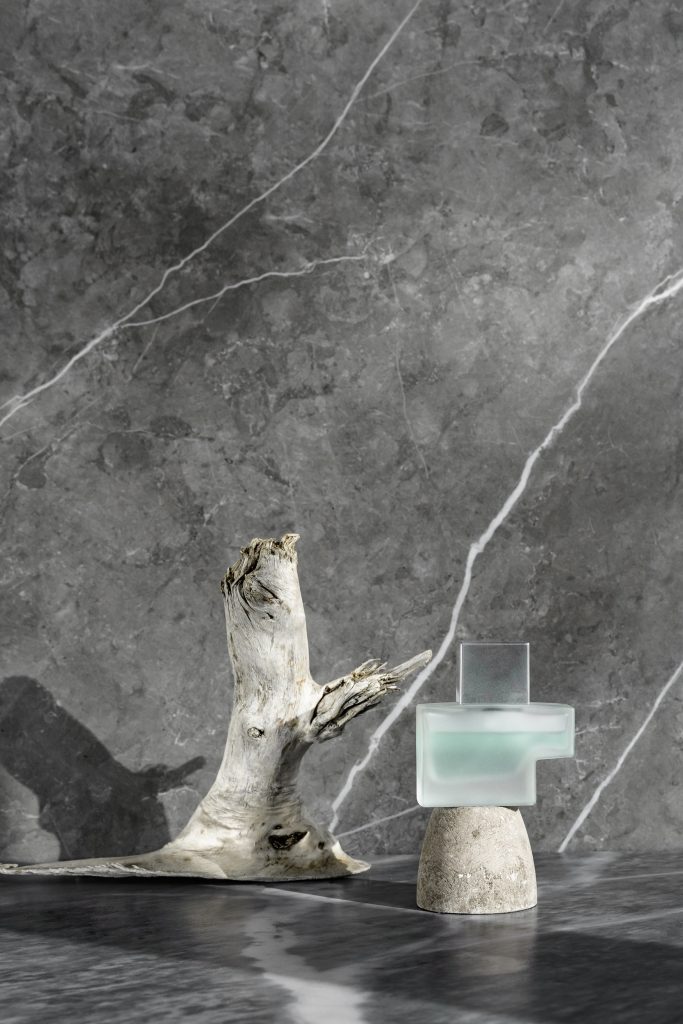

2. VEINS LOCATIONS: A practical method to discern quality in stone materials is examining the veins in natural stone. Marble, for instance, often showcases distinct veins that enhance its aesthetic appeal. High-quality marble tends to have evenly-spaced veins with consistent colouring. While limestone and granite can also exhibit veins, they are typically less pronounced than marble ones. It’s crucial to acknowledge the uniqueness of each stone slab, as the presence and appearance of veins can vary. It is identifying and analyzing veins that aid in selecting high-quality stone materials that contribute to a project’s beauty and durability, appreciating the distinctive veining patterns of different stones.

3. SPARKLE AND LUSTRE: The unparalleled polished brilliance of authentic marble is beyond the reach of synthetic stones, which can, at most, achieve a mediocre shine. To fully appreciate marble’s beauty, restoring its natural lustre is imperative. This process allows for a deeper understanding of its history and fosters a genuine appreciation for the stone in its present form.

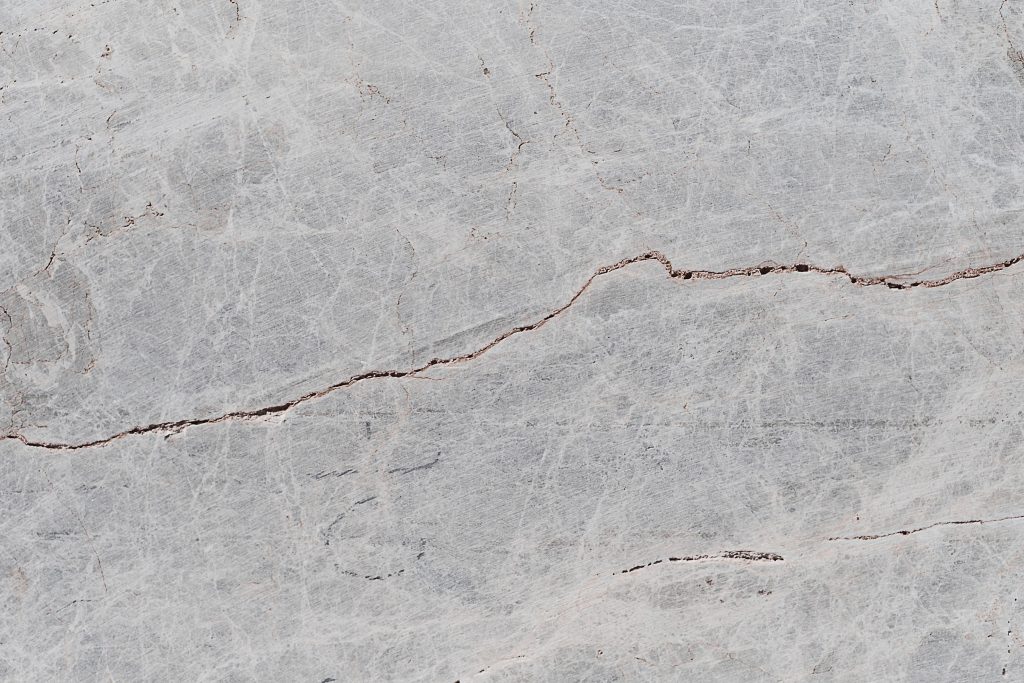

4. FISSURES AND APPEARANCE: When considering marble tiles, the inherent beauty of veining and cracks should be acknowledged, but it’s essential to recognize that these features can compromise the stone’s structural integrity. Examining the back of a tile allows for the observation of these imperfections. High-quality tiles are less likely to develop additional cracks or fractures upon breaking. In contrast, low-quality tiles may incorporate a fibreglass or epoxy mesh backing to enhance durability and prevent breakage.

5. MEASUREMENT AND ADJUSTMENT: The overall quality of a tile can be determined by its calibration or thickness. Opting for a thicker tile is advisable, especially for inherently flawed marble tiles, to minimize the risk of cracking. While imperfections enhance visual appeal, they may lead to cracking in thin tiles. Accurate calibration and measurement are crucial to ensure uniformity in tile size. Any deviation or misalignment during cutting can result in tiles with a trapezoidal shape, making it challenging to achieve consistent and tight grout lines. For a flat floor or counter, using tiles all the same size is recommended.

6. FRAGMENTS & SPLITS: The presence of broken or chipped marble tiles might signal a production defect. Over 5% of the tiles on the marble countertop display chips or cracks, which suggests that the tiles may be too brittle and prone to damage during cutting. While marbles can naturally develop chips or cracks over time, exceeding the 5% threshold indicates poor-quality tiles. Additionally, every side of the marble tile must be flawless, as any defects on the tiles signify inferior quality.

7. MENDED TILES: During manufacturing, factories may employ fillers to mend broken or chipped tiles. It’s essential to be aware that the reflective surface of the tile can expose dull spots when viewed at an angle to the light. Additionally, the marble quality in some tiles may need to meet the expected standards compared to other instances. When tiles are made from high-quality marble, the necessity for fillers is eliminated.

How We Perform Quality Control

Conducting quality control for natural stone entails a systematic procedure aimed at verifying adherence to defined standards and criteria. The following is a comprehensive guide on how to carry out quality control for natural stone.

Before Inspection: Before commencing any production, it is our consistent practice to define the specific standards that will govern the manufacturing process.

⇒ Define Standards: We establish clear and specific criteria for the natural stone based on factors such as colour, veining, thickness, finish, and structural integrity.

⇒ Select Representative Samples: Agreeing on the set of samples is very important. We generally prefer to lay large numbers of models showing every range of colours and veins that could go into the batches. In this case, we all know which types are acceptable or not.

Visual Inspection: This step constitutes the central aspect of any inspection involving natural stones, given the absence of automated machinery or systems designed to select stones based on their appearance. Consequently, the responsibility falls on visual quality control methods to assess the desired standards are met.

⇒ Random Pieces: We randomly select samples from different lots or batches to ensure that these samples represent the entire range of natural stones inspected.

⇒ Consistency Check: We compare the selected samples with the established standards and specifications to secure consistency across different batches or shipments.

⇒ Surface Quality: We inspect the stone’s surface for any visible defects, such as cracks, chips, scratches, or irregularities in colour or veining.

⇒ Treatment: We check for consistency in the finish (polished, honed, etc.) to establish the desired aesthetic.

⇒ Thickness Calibration: We measure the thickness of the stone using callipers or a thickness gauge to confirm that the thickness is consistent within acceptable tolerances.

⇒ Vein Inspection: We examine the veining patterns, if applicable. Veins should be evenly distributed to not affect the stone’s structural integrity.

⇒ Dimensional Accuracy: We check the dimensions of the stone, primarily if it is intended for specific installations that length, width, and edge details meet the specified requirements.

⇒ Compliance with Standards: Our job is to guarantee that the natural stone complies with industry standards and regulations applicable to the specific type of stone.

Technical Specification: The majority of natural stones undergoing processing in factories undergo technical specifications measurements conducted by various institutions or universities. However, it’s crucial to note that not all tests adhere to standardized and uniform criteria, necessitating caution when interpreting test results. In instances of specific projects, there is a need to reevaluate and renew the tests to ensure alignment with the unique specifications outlined for the project.

⇒ Testing for Durability: These are performance tests to assess the durability of the stone that may include impact resistance, abrasion resistance, and hardness tests.

⇒ Water Absorption Test: This test conducts a water absorption to determine the stone’s porosity. High water absorption can lead to issues like staining and deterioration.

⇒ Chemical Resistance Test: It assesses the stone’s resistance to common chemicals to ensure it can withstand these agents without damage.

After Inspection: At our company, we place a high value on customer satisfaction and ensuring that their orders are fulfilled correctly. We understand the importance of accurate feedback and inspection reports to provide transparency and clarity regarding the loading batches. It is imperative that the order requirements and received goods match, and we take the necessary steps to verify this with our customers to avoid any unforeseen issues or discrepancies. Our commitment to delivering top-notch service includes providing our customers with clear and detailed information so they can trust that their orders are handled with precision and care.

⇒ Documentation: We keep detailed records of the quality control process, including test results, inspections, and any deviations from the standards. We give a full report on the results.

⇒ Training: We continuously improve and update our technical knowledge, new materials, and recent production methods to recognize and evaluate different aspects of natural stone quality.